Dale Farm is a dairy co-operative based in Northern Ireland, owned and suppliedby 1,300 local farmers both in Northern Ireland and Great Britain and employing 1,200 staff across the Group.

At Dale Farm there is a focus on environ-mental compliance and reducing the environmental impact of the business. In relation to sustainability, the businessis particularly focused on addressing:

- water management

- energy conservation

- waste management

Dunmanbridge Solar Farm

The flagship Dale Farm sustainability project is the solar farm installation at the Dunmanbridge site near Cookstown. Completed in 2017, it’s one of the largestsolar farms of its kind in the industry in Europe. The 37-acre solar farm has 15,000 solar panels connected directly to the site and is also connected to the local electricity network to facilitate exporting excess generation to the main electricity grid in Northern Ireland. It supplies 25% of annual site demand, and over the past year it has supplied 7 million kWh of electricity that would power 1,800 homes for a year. During thesummer months in particular, there are periods when the site is running off grid completely. The project was recognised at the Sustainable Ireland Awards in 2018and was awarded the winner of the ‘Best Use of Renewable Energy Sources’.

Energy Efficiency Innovations

Boiler Optimisation: To ensure the most efficient technology is in place, theboilers were replaced in all sites across the Group and the boiler hot-well tanks were updated to minimise energy loss and optimise condensate recovery, which overlaps with water efficiency and reduction in waste. The installation of reverse osmosis treatment of the boiler feed water has led to reductions in chemical use and frequency of boiler blow down.

Gas conversion: In 2019, all sites conver-ted from heavy fuel oil to gas which led to significant improvements in relation to air quality, and, as a consequence, carbon dioxide emissions have been reduced by 2,500 tonnes. In addition to environmental improvements, therehave been cost savings due to using cleaner and more efficient and cheaperenergy sources.

Other energy efficiency measures:

- In 2020 all light fittings were replaced with low wattage LED which has led to a 50% reduction in electricity use across all sites

- An Economiser was installed on gas boilers which has resulted in a 5% efficiency improvement over the past 3 years

- Replacement of fixed speed aircom-pressors with fixed and variable speed high efficiency units

- Installation of roof mounted solar panels at 3 sites generating 200,000 kWh of electricity.

Waste to Energy

At the Dunmanbridge site, lactose permeate, a by- product from whey processing, is used to feed over 20 local AD plants, generating clean renewable energy. Over 20,000 tonnes of solids per annum are supplied to these plants all year round. Going forward, Dale Farm intends to use this bio-gas to create a closed loop system to recover and reuse some of the energy that these plants are generating, in processing facilities and in their transport fleet.

Processes

Water Management

Water is essential throughout the entire processing system, for example for cleaning equipment, and a number of initiatives have been introduced over the past four years to reduce overall consumption:

- Installation of additional boreholes at processing facilities and water treat-ment plants with the aim of reducing the amount of mains water usage

- Move from water to air purging in some applications

- Redesign of water systems to recover and reuse.

These measures have led to a 40% reduction in water usage across the Group’s manufacturing facilities.

Waste

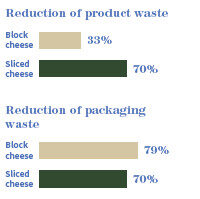

Significant reductions in packaging have been made through the LEAN programme, which has led to a 79% reduction in packaging waste on the Block Cheese line and a 70% reduction in product waste in the Sliced Cheese line. The LEAN programme has focussedon reducing the thickness of packaging, reducing the packaging around the product, and reducing waste through line reorganisation.